瀚能技术

一家集研发、制造,系统控制和技术服务为一体的节能技术领先型公司,致力于先进传热技术的研发和应用

绿色低温纯化

固体换热

余热回收利用

烟气脱白

瀚能开发和设计熔融结晶工艺技术,可提供量身定制的单体设备、集成橇装装置或现场安装系统。

熔融结晶是一种根据待分离物质之间凝固点不同而实现物质分离提纯的方法,是一种低能耗的有机物清洁分离工艺,对沸点接近的烃类、同分异构体和热敏材料等特殊物系分离效率高,超纯物质的制备是熔融结晶的特有优势。

瀚能固体换热技术由一系列平行排列的枕板和波纹板组成。枕板和波纹板分别组成热交换单元,通过堆叠多个热交换单元,可以实现较大的传热面积。 在枕板式换热器中,热介质通过枕板与波纹板之间的空隙流动,与另一侧的冷介质进行热交换。枕板和波纹板之间的空隙形成了流通通道,热介质和冷介质通过不同的流通通道分别流动,从而实现热交换。

瀚能自主研发Pillowplate枕型传热板,采用激光焊接技术,一体鼓胀成型,且皆为不锈钢以上材质。基于我司枕型传热板技术,研发产品有板式气水换热器、板式气气换热器,开发一系列余热回收系统:涵盖固、液、气三态介质余热回收系统,从高温到中低温余热的全面再利用,转化为客户需求的利用方向:可用于冬季供暖、预热锅炉凝水、夏季制冷、余热发电等。

瀚能自主研发Pillowplate枕型传热板,采用激光焊接技术,一体鼓胀成型,且皆为不锈钢以上材质。基于我司枕型传热板技术,板式气水换热器、板式气气换热器。不仅结合自身产品设计一套消白系统(已申请专利:专利号 ZL 2021 2 1696521.7),应用实际案例效果显著,客户称赞非常满意!与此同时瀚能不断创新,在消白系统基础上将余热回收融入其中,设计一套消白系统(已申请专利:专利号 ZL 2021 2 1865550.1),在消白的同时,将低温余热加以回收产热水和制冷,把节能环保尽可能做到更好!

ABOUT US

瀚能科技

瀚能(苏州)节能科技有限公司是一家集研发、制造,系统控制和技术服务为一体的节能技术优良型公司,致力于先进传热技术的研发和应用,开发了绿色低温纯化,固体换热,余热回收利用,烟气脱白等优良技术及相关产品。公司拥有优良的自动激光焊接技术及精益化加工、组装车间,已累计服务于全球600多家客户1000多个项目,在诸多细分行业拥有了成熟的产品和系统的解决方案。

交付项目

厂房面积

总人数

应用领域

了解更多 +APPLICATION

已累计服务于全球600多家客户1000多个项目,在诸多细分行业拥有了成熟的产品和系统的解决方案。

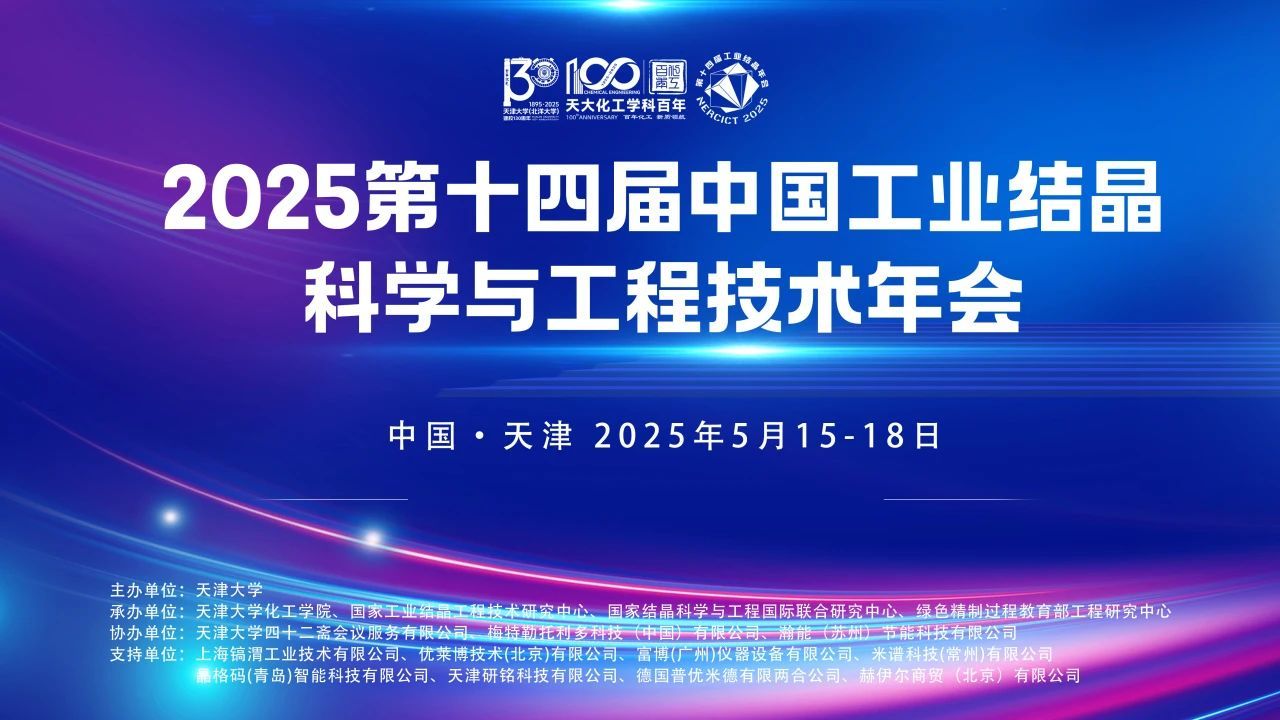

新闻动态

NEWS INFORMATION