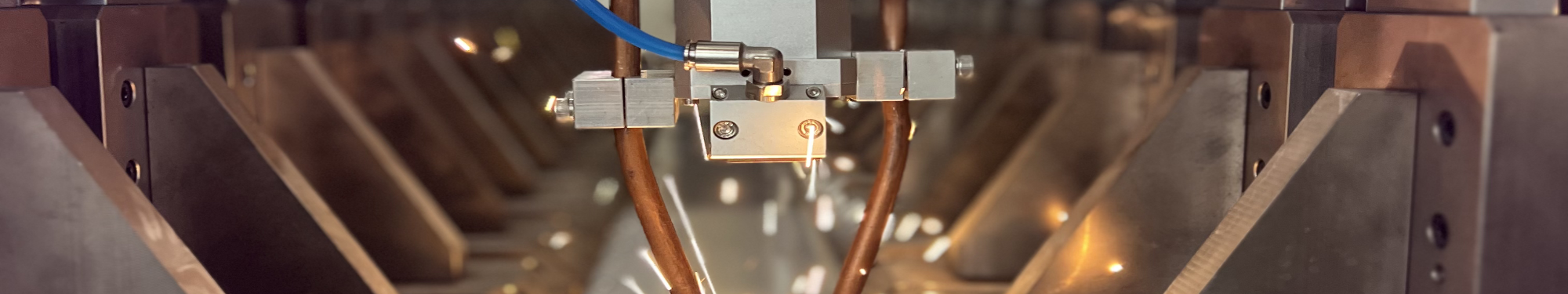

Cooling: The material enters the heat exchanger from the top, and fills the heat exchanger inside to the feed bin, so that the material inundate the heat exchange module. At this time, the cooling water enters the heat exchange module plate from the lower end of the heat exchange module and is discharged from the upper part of the heat exchange module. At the same time, the top of the feed bin adjusts the discharge speed of the feeder according to the feed amount, and maintains the material level height in the feed bin.

During operation, the material flows uniformly and completely between the plates of the heat exchange module, and achieves the purpose of cooling by heat exchange with the inner cooling water wall of the heat exchange plate.

Energy saving up to 90% : low heat loss. Compared with the traditional technology, the energy saving effect is obvious, and some can reach 90%.

Low emission: Running in a fully closed silo type container, the auxiliary gas consumption is small, and the environmental pressure is greatly reduced.

Loss degradation is almost zero: solid dense phase transport and the excellent flow state achieved by the pillow heat transfer plate group, heat transfer is full and uniform, and material loss is almost zero.

Small footprint, strong expansion: vertical installation, small footprint. Simple and compact structure; Modular design, after installation can still be expanded according to capacity requirements.

Simple maintenance and low cost: the plate solid heat exchanger is designed with a quick door, which is convenient for users to quickly open the door panel for internal maintenance and cleaning of the equipment.

Chemical powder: Urea, nitrogen, phosphorus and potassium compound fertilizer, phosphate fertilizer, ammonium sulfate, ammonium nitrate sulfate, potassium sulfate, potassium nitrate

Chemical products: Boric acid, calcium chloride, calcium hypochlorite, defluorinated phosphate, potassium chloride, sodium chloride, sodium bisulfate, sodium fluoborate, sodium percarbonate, tetrapylium pyrophosphate, tricalcium phosphate, sodium carbotrite, ferrous phosphate, calcium ammonium nitrate

Minerals and catalysts: powder coke, activated carbon, carbon black, coal powder, alumina, catalyst, chromium sand, clay, copper powder, limestone, nickel chloride, nickel kiln ash, nickel oxide, petroleum coke, phosphate rock, resin coated sand, quartz sand, foundry sand, clay, fluidized bed cracking catalyst

Polymers: PE polyethylene, PP polypropylene, PA nylon, PC polychloroprene, PET polyester, PVC polyvinyl chloride, TPU thermoplastic polyurethane elastomer, EPR ethylene propylene rubber, ABS acrylonitrile-butadiene-styrene plastic, POM polyformaldehyde, EVOH, LDPE

Mobile Access

Mobile Access

Tiktok QR code

Tiktok QR code

Address:

No. 9 Guanshan Road/No. 8 Jinyan Road, Suzhou High tech Development Zone

Phone:

400-688-9325

Email:

szsales@sehenstar.com

Website:

www.hanertech.com / www.sehenstar.cn

CopyRight:HANERTECH Energy Technology (SuZhou) Co., Ltd Record No:苏ICP备14018856号

Technical Support:晨光科技11

Product Information

Quantity

Unit

Piece

Support order samples, customization, wholesale direct, and complete payment. If the product you look for does not have corresponding customized content, pls fill out the form below to contact us, and we will reply ASAP.