Hanertech develops and designs the technology of molten crystallization processes, providing tailored individual equipment, integrated sled-mounted devices, or on-site installation systems. Molten crystallization is a method of substance separation and purification based on the different solidification points of the substances. It is a low-energy and environmentally friendly process for clean organic substance separation. It exhibits high efficiency in separating substances with close boiling points, such as hydrocarbons, isomers, and thermally sensitive materials. The preparation of ultra-pure substances is a unique advantage of molten crystallization.

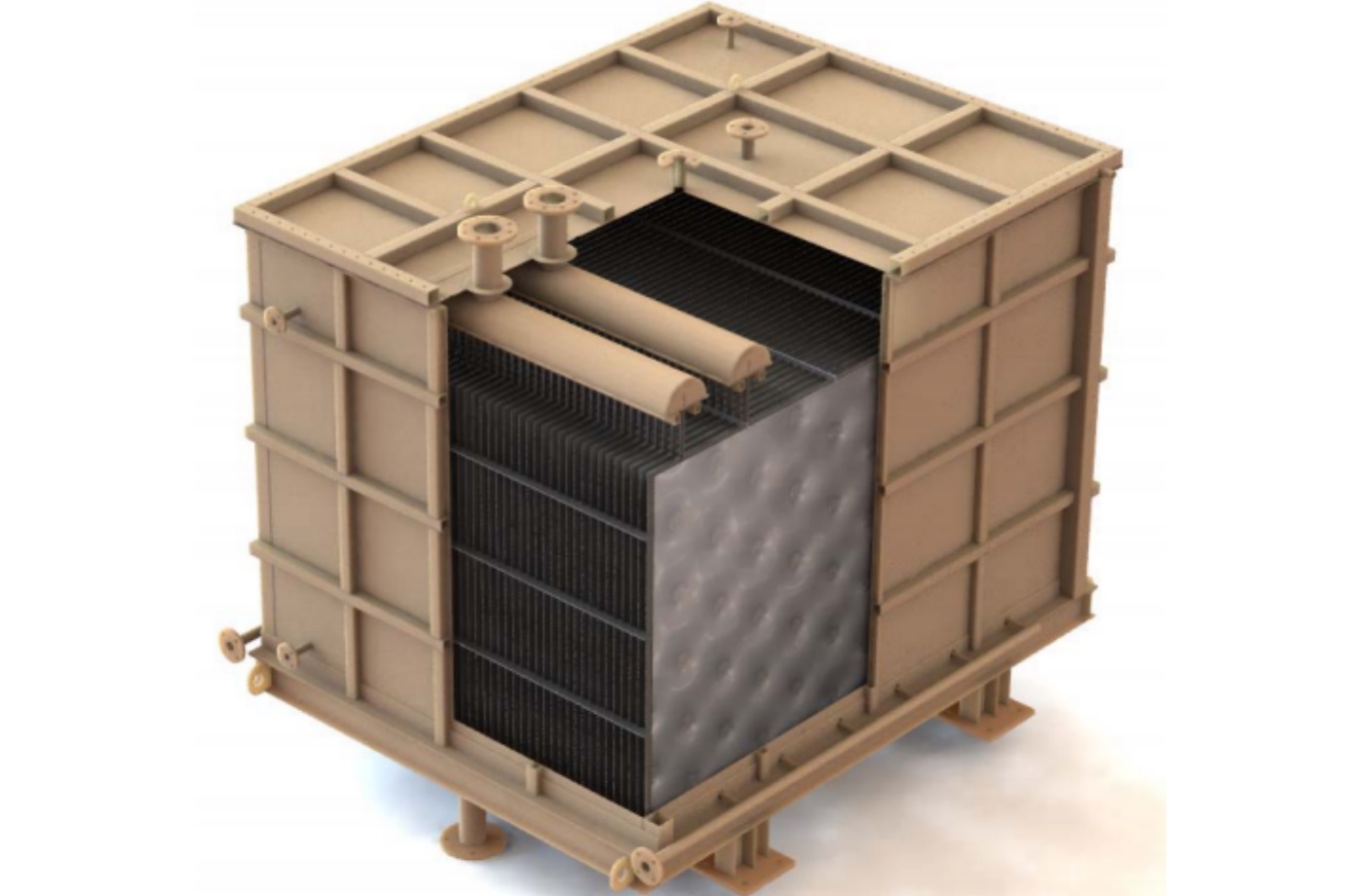

We utilize a novel technique called static stepwise crystallization for separation and purification. With the use of specially designed crystallization plates and precision temperature control units developed in-house, the temperature of the medium inside the plate is precisely controlled. This gradual control of temperature transitions the substance to be purified from a saturated state to a supersaturated state, thereby inducing the crystallization and precipitation of the target substance. A crystalline layer gradually forms on the plate's surface. The molten crystallization process involves three stages: cooling crystallization, warming sweating, and heating melting, all contributing to the production of high-purity products.

The product purity is high, up to 99.99%

Environmentally friendly, do not add any other solvent, reduce environmental pollution; Equipment atmospheric pressure closed operation, zero exhaust emissions

High operation reliability, normal pressure, low temperature operation, long service life of equipment; High degree of automation

High efficiency, low energy efficiency, only 10% to 30% of the rectification technology

It has a wide range of applications and is very suitable for heat sensitive, isomer, azeotrope and other substances

Electronic chemicals: Ethylene Carbonate/EC,Dimethyl Carbonate/DMC,Vinylene Carbonate/VC,Fluoroethylene Carbonate/FEC,Phosphoric Acid

Biosynthetic materials: dimethyl succinate, lactide, pentenediamine, long chain dibasic acid

Coal chemical industry: refined naphthalene, Fischer-Tropsch wax, cresol, naphthol

Fine chemicals: Benzoic acid, phenylenediamine, dichlorobenzene, chloroacetic acid, nitrochlorobenzene

Polymer monomers: bisphenol A, acrylic acid, caprolactam, dimethyl terephthalate, hexanediamine

Petrochemical: maleic anhydride, p-xylene, m-xylene, acetonitrile

Mobile Access

Mobile Access

Tiktok QR code

Tiktok QR code

Address:

No. 9 Guanshan Road/No. 8 Jinyan Road, Suzhou High tech Development Zone

Phone:

400-688-9325

Email:

szsales@sehenstar.com

Website:

www.hanertech.com / www.sehenstar.cn

CopyRight:HANERTECH Energy Technology (SuZhou) Co., Ltd Record No:苏ICP备14018856号

Technical Support:晨光科技11

Product Information

Quantity

Unit

Piece

Support order samples, customization, wholesale direct, and complete payment. If the product you look for does not have corresponding customized content, pls fill out the form below to contact us, and we will reply ASAP.